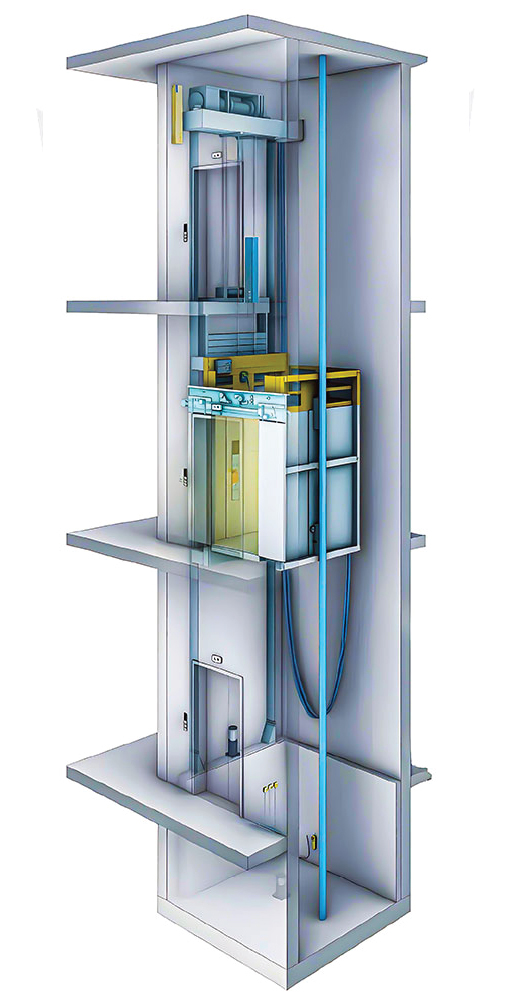

What are MRL Elevators?

Machine Room Less (MRL) Elevators are a modern type of elevator that eliminates the need for a separate machine room. Instead, the machinery and control systems are compactly integrated within the elevator shaft, typically at the top of the elevator car or the side of the hoistway. These elevators are an excellent choice for low- to mid-rise buildings, offering space-saving benefits, energy efficiency, and sleek design.

MRL Cabinet Nice Series EN81-20

MRL Cabinet Nice Series EN81-20" likely refers to an elevator cabinet designed to meet the safety and performance standards of EN81-20. This European standard covers passenger and goods passenger elevators.

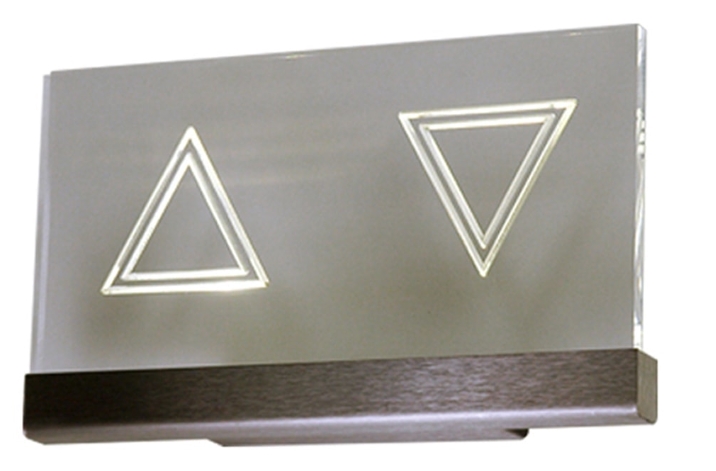

Hall Lantern

An illuminated overhead indicator for elevator arrival and direction, ensuring clear, user-friendly navigation in busy hallways.

MORE PRODUCTS

MRL Operating Panel (Landing Floor)

Sleek, user-friendly call station with LED indicators, ensuring smooth, reliable elevator travel at every stop.

MORE PRODUCTS

Door Controller EN81-20 Compliant Door Nudging

Ensures safe, gentle door closure by prompting passengers to clear the doorway, meeting modern safety standards.

MORE PRODUCTS

LOP

A user-friendly landing panel offering quick floor calls, visual indicators, and streamlined passenger flow at every level.

MORE PRODUCTS

COP

The in-cabin control panel for passengers, enabling floor selection, door functions, and emergency signals with clear, intuitive interfaces.

MORE PRODUCTS

Elevator Rope

A high-tensile steel or synthetic cable that supports and moves the elevator car, ensuring reliable, controlled travel within the shaft.

MORE PRODUCTS

Elevator inspection Box

A secure enclosure enabling technicians to safely perform service checks, control movement, and override normal elevator operations.

MORE PRODUCTS

Let’s Start Work

Together

Please feel free to contact us. We will get back to you as soon as possible. Or just call us now.

Advantages of MRl Elevators

-

Space Efficiency : Eliminates the need for a machine room, maximizing usable building space.

-

Cost Savings : Lower construction costs due to reduced structural modifications.

-

Eco-Friendly : Regenerative drives and LED lighting help lower energy consumption.

-

Ease of Installation : Compact machinery simplifies the installation process.

-

Modern Technology : Offers features like smart control panels, voice activation, and destination dispatch systems.

Key Features of MRL Elevators

-

Compact and Space-Saving Design : No separate machine room is required, making MRL elevators ideal for buildings with limited space or architectural constraints.

-

Energy Efficiency : Equipped with energy-efficient traction systems, including gearless motors and regenerative drives, which reduce electricity consumption and operational costs.

-

Quiet and Smooth Operation : Advanced engineering ensures a whisper-quiet and vibration-free ride, enhancing user comfort.

-

Modern Aesthetic : The compact design allows for sleek and stylish elevator cabins that blend seamlessly with modern architectural designs.

-

Environmentally Friendly : Uses less space and fewer construction materials, contributing to a lower environmental impact during installation.

How MRL Elevators Work

Core Mechanism: MRL elevators operate using steel ropes or belts that pass over a traction sheave (pulley). The sheave is connected to a compact motor, typically located at the top of the shaft or attached to the elevator car.

Gearless Technology: Most MRL elevators use gearless motors for smoother operation, higher efficiency, and reduced noise.

Integrated Controls: The control panel for MRL elevators is placed within the elevator shaft or in a nearby accessible location, eliminating the need for a dedicated machine room.

Advanced Technology: Smart systems manage the elevator’s speed, stopping precision, and user calls, ensuring smooth and reliable operation.

Balancing the Load: A counterweight system balances the elevator car, reducing the energy required to move the car up or down. The counterweight travels on the opposite side of the car within the shaft.

Call Activation: The user presses a button or enters a floor number on the control panel.

Motor Activation: The motor engages, moving the traction ropes and counterweight system to lift or lower the car.

Smooth Movement: Gearless technology ensures vibration-free and quiet movement.

Precise Stopping: The control system regulates the car’s position, ensuring exact alignment with each floor.

Compact Motor Placement: Unlike traditional elevators, MRL elevators have their motors located within the shaft, either on the car or at the side of the hoistway.

Energy-Efficient Drives: Regenerative drives convert braking energy into reusable electricity, making the system more energy-efficient.

Braking System: Electromagnetic brakes engage automatically in case of power loss or emergency stops.

Overload Detection: Sensors monitor the car’s weight and prevent operation if overloaded.

Backup Power: Allows the elevator to safely lower to the nearest floor during power outages.

Door Interlocks: Prevent the doors from opening unless the car is securely stopped at a floor.

Frequently Asked Questions (FAQs)

It’s a design that places the drive system in the hoistway, removing the need for a separate machine room.

Traditional elevators have a dedicated machine room; MRL models house machinery within or atop the shaft.

Yes. MRL elevators meet the same safety codes as conventional systems.

Not necessarily. Access is through the hoistway, but modern designs are service-friendly.

Typically low- to mid-rise structures, though higher floors may be possible based on model and code.

Often, yes. Many use gearless drives or efficient motors, reducing power consumption.

No. MRL systems match traditional elevators in speed, capacity, and optional features.

Eliminating a machine room can reduce construction costs and free up space.

Modern dampening keeps noise low, but some slight sound may be noticeable near the machinery.

The equipment can be slightly pricier, but overall savings on construction and energy can offset that.