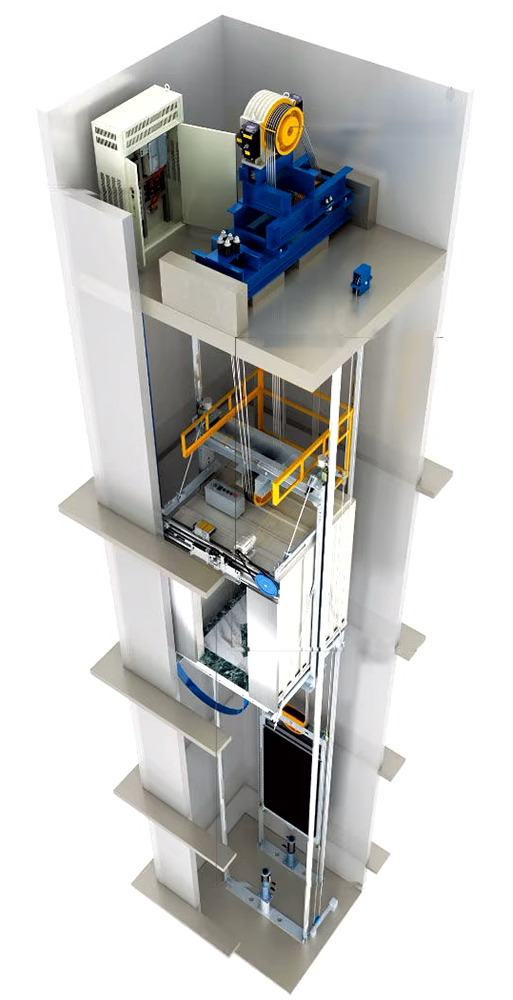

What are MRA Elevators?

Machine Room Above (MRA) Elevators are a type of traction elevator where the machinery and control systems are housed in a machine room located above the elevator shaft. This design is common in mid- to high-rise buildings, offering high capacity, speed, and durability. The machine room provides easy access for maintenance and ensures smooth and efficient operation.

Monarch Nice 3000+

A modern elevator control system offering reliable, efficient performance while optimizing passenger comfort and energy usage.

MORE PRODUCTS

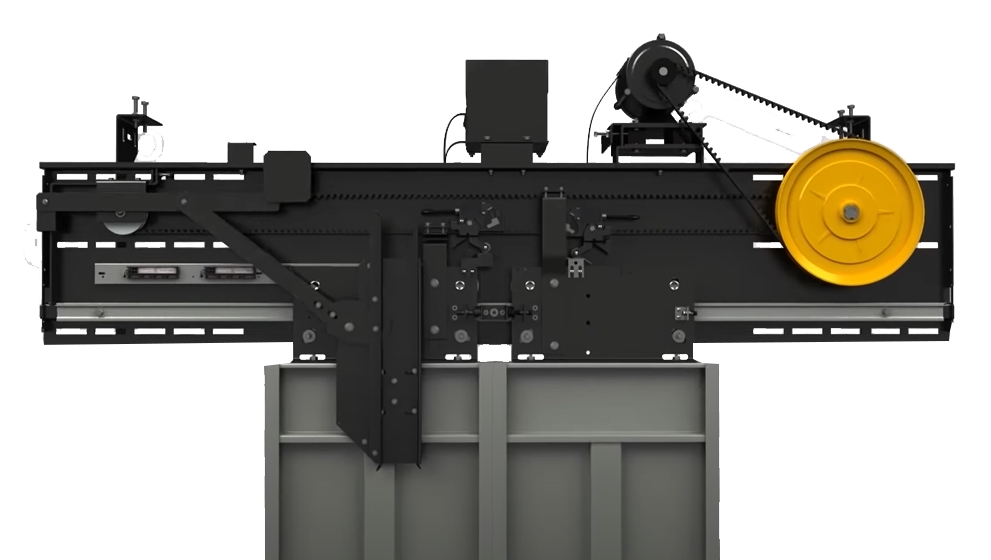

Gearless Machine

A type of elevator machine that operates without gears for smoother performance.

MORE PRODUCTS

Speed Governor

A safety device that monitors and controls an elevator’s travel speed, preventing overspeed by triggering emergency brakes when necessary.

MORE PRODUCTS

Car Door Operator

A mechanism that smoothly opens and closes the elevator car doors, ensuring safe entry and exit for passengers.

MORE PRODUCTS

Door Panel

The protective barrier that seals the elevator entrance, keeping passengers secure and preventing unauthorized access when the elevator is in motion.

MORE PRODUCTS

Cabin

The enclosed space where passengers or goods travel vertically, designed for safety, comfort, and efficient use of space.

MORE PRODUCTS

COP & LOP

Car Operating Panel (COP): The control panel inside an elevator cabin that allows passengers to select floors, open or close doors, and activate emergency signals.

Landing Operating Panel (LOP): The panel at each landing or floor, enabling users to call the elevator and indicate their desired travel direction.

MORE PRODUCTS

Counter Weight

A weighted component that balances the elevator car, reducing the motor’s workload and enhancing overall energy efficiency and stability.

MORE PRODUCTS

Hydraulic Buffer

A safety device placed at the bottom of the shaft to absorb and cushion the elevator’s descent if it travels beyond its normal stopping point.

MORE PRODUCTS

Let’s Start Work

Together

Please feel free to contact us. We will get back to you as soon as possible. Or just call us now.

Advantages of MRA Elevators

-

High Load Capacity: Suitable for heavy-duty applications and high-traffic environments.

-

Smooth and Quiet Operation: Advanced traction systems ensure a comfortable ride.

-

Proven Reliability: Trusted technology for long-term performance in demanding settings.

-

Support for Higher Speeds: Ideal for high-rise buildings where speed is a priority.

-

Enhanced Safety Features: Equipped with advanced systems like emergency braking and backup power for user safety.

Key Features of MRA Elevators

-

High Capacity and Performance: Designed for heavy traffic and high-load applications, making them ideal for commercial and residential towers.

-

Durable and Reliable : Built with robust materials and proven technology, MRA elevators are long-lasting and perform consistently even under high usage.

-

Ease of Maintenance: The dedicated machine room allows technicians easy access to equipment, reducing maintenance time and improving efficiency.

-

Flexible Travel Height: Suitable for mid- to high-rise buildings, as they support extended travel heights with precision and stability.

How MRA Elevators Work

- Core Mechanism: MRA elevators use steel ropes or belts that pass over a traction sheave connected to a motor located in the machine room above the shaft.

- Motor and Gearbox: The motor (geared or gearless) drives the traction sheave. In geared systems, a gearbox controls speed. In gearless systems, the motor directly drives the sheave, allowing for smoother and faster operation.

Advanced Controls: The elevator’s control panel in the machine room manages speed, acceleration, braking, and leveling at floors.

Destination and Call Systems: Users request floors via buttons or advanced input panels. The control system calculates the most efficient route, ensuring smooth travel and accurate stopping.

Load Balancing: A counterweight runs on a separate track on the opposite side of the shaft. This balance reduces the energy needed to lift or lower the car, making the system more efficient.

Energy Efficiency: By counterbalancing the car’s weight, the motor works less, resulting in lower power consumption and improved efficiency, especially in high-rise buildings.

Floor Request: A passenger presses a button or enters a destination.

Motor Activation: The control system engages the motor, causing the ropes or belts to move the car up or down.

Precision Stopping: Sensors and braking systems ensure the car stops exactly level with the selected floor.

Door Operation: Doors open only when the car is securely at a floor, ensuring safe entry and exit.

Dedicated Space: The machine room, located above the elevator shaft, houses the motor, control panel, and other essential components.

Easy Maintenance: With all critical machinery in one accessible room, technicians can perform maintenance, repairs, and inspections more efficiently without disrupting the elevator’s main shaft area.

Emergency Brakes: If ropes slacken or there’s a malfunction, the elevator’s safety brakes engage, stopping the car.

Overload Sensors: If the load exceeds the car’s capacity, the elevator won’t move until the excess weight is removed.

Backup Power: In case of a power outage, backup systems can safely lower the car to the nearest floor.

Frequently Asked Questions (FAQs)

A Machine Room Above (MRA) elevator is designed with the main machinery—like the motor and controller—located in a dedicated room at the top of the hoistway. This setup differs from Machine-Room-Less (MRL) elevators, where the machinery is integrated into the shaft itself.

Yes. With a MRA design, technicians have a dedicated space at the top of the building to access the equipment, which often simplifies servicing and can reduce downtime.

Absolutely. MRA elevators are commonly used for mid- to high-rise buildings, as the separate machine room can accommodate more powerful motors and control systems needed for taller structures.

Placing the machinery at the top typically reduces noise in lower floors since the motor and associated components are further away from those areas. You may notice some operational sounds in or near the top floor, however.

Costs vary depending on factors like building height, capacity, and materials. In general, the cost may be comparable to other traditional designs, but the need for a dedicated machine room could affect construction expenses.

Yes. The location of the machinery doesn’t significantly affect energy efficiency. Many MRA elevators include energy-saving features like regenerative drives and efficient motors, which help reduce operating costs.

Possibly. A structural assessment by a professional is recommended to ensure the building can support the added load of the machinery and dedicated room. In many cases, modern buildings are designed with this in mind.

Maintenance frequency depends on usage and local regulations. Typically, monthly or quarterly inspections are recommended. Regular servicing ensures safety, reduces downtime, and extends the elevator’s lifespan.